Sucker Rods: API Standard, High-Strength, and Corrosion Resistant

Exceed (Canada) is the Canadian division of Nine Ring Petroleum Machinery Co. Ltd. in China; the largest sucker rod manufacturer in the world (150 million ft per year).

Our 35 acre manufacturing facility is equipped with a fully automated production line and is 100% computer controlled. We are ISO 9001 and API certified and maintain 100% API compliance through consistent and rigorous inspection and monitoring programs.

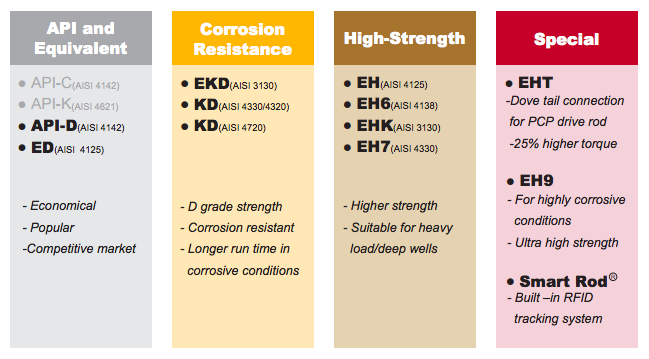

Exceed offers a variety of innovative and advanced styles of sucker rod products that provide superior performance, even in the toughest downhole conditions. Exceed’s pin and coupling threads are rolled and cold-forged for superior strength, and are either phosphated or copper-coated to avoid thread galling issues. We provide complete sucker rod solutions offered in the following product lines:

- ED rod:

Smaller and stronger than traditional API D Grade rods - EKD rod:

D Grade strength for longer run times in corrosive conditions - EH rod:

Ultra-high strength suitable for heavy load/deep wells

EH9 SUCKER RODS REDEFINE ANTI-CORROSION

For corrosive wells, rod manufacturers normally rely on additional inhibiting chemical treatment in the well to ensure rod life. This approach often falls short in environments with high H2S, CO2 and bacteria concentrations.

After years of research and testing, our engineers refined special Chromium alloy steel with a significantly reduced Carbon content and a high Chromium content (11-12%) and developed EH9.

Significantly reduced Carbon content eliminates carbon-chromium compound precipitation along grain boundaries and improves the material’s abrasion performance.

This new rod not only withstands extreme corrosion, it also delivers ultra-high tensile and fatigue performance, making it the rod of choice for the toughest wells.

Smart Rod®: Built-in RFID tracking system

To help customers better manage their rod assets and improve operation efficiency, we developed the Smart-Rod technology. Each Smart-Rod has a RFID chip embedded inside the rod pin, giving it a unique ID that can be traced throughout the rod’s life cycle.

A handheld reader can conveniently identify each rod during work over operations and asset management activities. Rod information collected, combined with the well information database, can then be used to guide decisions to confidently reuse, categorize and locate used sucker rods from a particular batch reliably and confidently.

| Exceed | Product Category | Steel | Tensile Strength (ksi) | Competitors' Product |

| D | API-D Grade | 4142 | 120 - 140 | API D / 78 [Norris] |

| ED | Improved API - D Grade | 4125 | 126 - 145 | None |

| KD | Corrosion Resistance | 4320 | 120 - 140 | 90 [Norris] |

| Corrosion Resistance | 4330 | 125 - 140 | 75 [Norris] / D Special [Tenaris] | |

| Corrosion Resistance | 4720 | 144 - 180 | KD [Weatherford] | |

| EKD | Corrosion Resistance | 3130 | 140 - 150 | S-87 [Weatherford] |

| EH | High Strength | 4125 | 140 - 150 | None |

| EH6 | High Strength | 4138 | 140 - 155 | 96 [Norris] |

| EH7 | High Strength / Avg. Corrosion Resistance | 4330 | 140 - 170 | 97 [Norris] |

| EHK | High Strength / Avg. Corrosion Resistance | 3130 | 140 - 170 | S-88 [Weatherford] |

| EH9 | High Strength High Corrosion Resistance | Stainless steel 11-12% Cr | 140 - 170 | None |

| EHT | PCP Rod (Dove tail connection) | 4125 | 144 - 180 | None |

Sucker Rods are available in 25ft/26ft/30 ft. Pony Rods are available in 2, 4, 6, 8 10 and 12 ft. API standard connection.

Accessories| COUPLINGS | POLISHED ROD | SINKER BARS | ROD GUIDE |

| Grade | Grade | Grade | Type |

| T/SM/HS | D, D-SM, High-strength | 1/2/3(C/K/D) | Various types available |

| Size | Diameter | Length | Size |

| Full/Slim | 1⅛” / 1¼”/ 1½” | 25 ′ /30 ′ | 2” / 2½” / 3” |

| Material | Material | Diameter | Material |

| 40 Cr | 4140 | All sizes 1¼” to 1¾” | PA6 |

| 4130 | 1045 | Material | PPA |

| 8630 | 25CrMoA | 1045 | |

| 4330 | |||

| 4142 |